Ever feel like you’re wrestling with a tangle of wires, unsure how to join them safely and securely? It’s a common feeling when you’re tackling any electrical project. Choosing the right wire connector can seem overwhelming. There are so many different types, sizes, and shapes! Picking the wrong one can lead to loose connections, safety hazards, or just a job that doesn’t last.

But don’t worry! You don’t need to be an electrician to understand these crucial little parts. Understanding wire connectors is key to making your home repairs or DIY projects work right and stay safe. This post will break down the mystery behind wire connectors, making it easy to see which one fits your needs perfectly.

By the end of this guide, you will know the difference between the most popular connectors and feel confident picking the best one for your next task. Ready to stop guessing and start connecting with certainty? Let’s dive into the world of wire connectors!

Top Wire Connectors Recommendations

- Connect any combination of solid, stranded, and flexible copper wires faster and more reliably

- Terminates 24-12 AWG for 221-41x, 20-12 AWG for 221-2401 solid

- UL Listed, Genuine WAGO LEVER NUTS

- Visually inspect for proper strip length and complete wire insertion through its transparent housing

- You wil get the wire connectors assortment kit includes various wire gauges in a box, 455 pieces, 26-10 AWG, different color-coded tubing for easy identification.

- Shrinkable tubing, hot melt adhesive rings, solder sleeve, provide a rock-solid connection, good electrical conductivity, greater pull strength, hold up better to moisture.

- Solder Seal Wire Connectors are built to last, made of high-quality polyolefine, waterproof, strong resistant to corrosion and chemical erosion, compliant with ROHS, SGS, and CE standards.

- All-in-one step solder and seal process. Solderless, crimpless, you just need a heat gun, with evenly heated, butt will shrink quickly and adhere to wire insulation.

- Thick Pure Copper Butt Connectors:BAALA Non Insulated butt connectors are made of C11000 pure copper, with the best conductivity and shape-shaping. The lowest resistivity reduces heat generation and extends the life of the wire. Perfect shapeability facilitates wire crimping and does not cause terminals to break. Pure copper has marine-grade corrosion resistance and is suitable for use in any extreme environment.

- Flared Barrel Wire Butt Connectors: These butt splice connectors feature a flared barrel design for easy wire insertion.

- With 3:1 Ratio Dual Wall Heat Shrink Tubing: BAALA wire splice connectors are paired with 3:1 Ratio Heat Shrink Tubing. BAALA heat shrink tubing contains a heat-activated adhesive that creates a seal, preventing water, solvents, and salt from entering the cable.

- Strong Connection: Thicker and longer pure copper butt connectors provide a stronger crimp, ensuring your wire will never slip out of these wire connectors.

- Time Saver: Solderless,crimpless, all you need is just a heat gun to finish the joint, much faster and easier than the old way

- Fit for Confined and Narrow Spaces: Can be bent after connection and no need to crimp or solder in the confined area, just control the temperature via a heat gun

- Waterproof and Seal Performance: There is two hot melt waterproof adhesive rings in each butt connector, which help it hold up better to moisture

- High Temperature Proof in A Short Time: Use exclusive material in the butt connectors to avoid shrink tubing melting before solder ring

- Self-Stripping electrical tap connectors - Nilight self-stripping electrical t-tap connectors makes tapping into an existing wire a quick and easy job

- Versatile kit - 60 piece T-Tap Wire Connectors plus 60 piece; Male Quick Disconnects will last for numerous wiring projects. Marine, automotive, scientific, home wiring projects - you name it

- Thick tinned copper contacts - Thicker tinned copper contacts provide maximum conductivity and prevents the wire from shorting out efficiently

- Quality t-tap connector housing - Quick splice T-Tap connectors will securely lock on the wire. Plastic housing will not open after it has been snapped on the wire

- INSULATION MATERIAL: These electrical wire connectors are made of plastic shell. The nylon shaped shell has thick wall, high hardness and is not easy to aging. It can effectively prevent the unstable connection of leakage box and enhance the safety and insulation.

- STRONG SPRING DESIGN: These Wire Caps are made of metal spring, which is inserted to ensure a stable connection to each application. Preventing the connection from falling off due to instability. Strong wiring, good conductivity.

- COMPACT AND PORTABLE: The electrical wire nuts are a round base with model and specification on the top of the wire connector, compact and portable. The packaging is made of transparent plastic moulded partition storage box to keep different wire connectors separate. There are 5 kinds of nuts with different colors. Special size corresponds to special colors for easy identification and selection. Clear, easy to store and use.

- HIGHT COST PERFORMANCE: Complete specifications, 5 different specifications of wire nuts, special size of special colors. The package includes 50pcs Grey, 50pcs Blue, 50pcs Orange, 18pcs Yellow, 12pcs Red. The most common size can be used for everyday electrical wiring projects and applications.

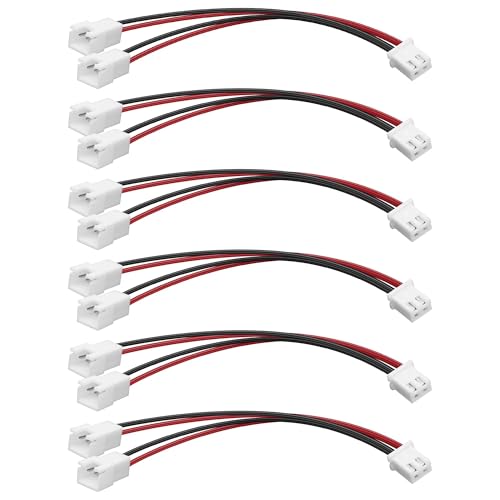

- XH 2.54 2-pin connector terminal wire is used for power supply connection of small electronic devices, and the 2-pin XH2.54 1/2 adapter terminal wire is only used for power supply and has no other functions

- Connector type: 2Pin XH 2.54 male terminal to 2 * 2Pin XH 2.54 female terminal; Terminal Pitch: 2.54mm; Pin size: 2Pin; Wire model: 24AWG; Cable color: red and black; Power supply: Supports 5-8A current at low voltage

- 2-pin XH2.54mm 1 to 2 connector uses tin plated copper conductors, PVC insulated housing, and 24AWG pure copper wire core to enhance conductivity and provide reliable connections for DIY circuits and PCB board wiring

- Easy to install: The fan interface that is easy to connect to the motherboard allows for simultaneous power supply for two fans. Compact and convenient, flexible wiring in small spaces

- 【Reusable & Efficient】 Wire connectors push-in are reusable, saving resources. The led light strip connectors are suitable for hard and flexible wires, and the independent shrapnel design is suitable for different wires. The led strip connectors can help your wiring operation, fast, time-saving, and labor-saving, and a double wire plug in connector will be a good helper for you.

- 【High Quality Material】 These led strip lights connectors are made of high-quality PA66 nylon, which has high stability and is suitable for long-term use. The led connectors for strip lights are electric shock resistant, voltage resistant, and have a certain degree of insulation so that you can use it with confidence.

- 【Easy To Use】 The low voltage wire connector is easy to operate, only need to open the handle, push the stripped wire into the card slot, press the wire tightly, and finally press the control lever tightly, simple and convenient, easy to operate.

- 【Wide Applications】 Low voltage connectors are suitable for all household wiring, you can use them for fans, sockets, switches, speakers, lamps, motorcycles, cars, led light strips, etc. led strip connectors 2 pin can improve your work efficiency, save time, and save electrical energy consumption.

Choosing the Right Wire Connectors: Your Complete Buying Guide

Wire connectors are small but mighty tools. They help join electrical wires safely and securely. Whether you are a DIY beginner or an experienced electrician, picking the correct connector is vital for a safe electrical setup. This guide will help you make the best choice.

1. Key Features to Look For

When you shop for wire connectors, several features matter most. These features ensure a strong, reliable connection.

- Connection Type: Different jobs need different connectors. Some common types are twist-on (like wire nuts), push-in, lever nuts, and crimp connectors. Know which type fits your project.

- Wire Gauge Capacity: Wires come in different thicknesses, measured in gauge (AWG). Check the connector’s packaging. It must clearly state the minimum and maximum wire sizes it can handle. Using the wrong size can lead to overheating or poor connection.

- Insulation and Safety Rating: Good connectors have strong insulation. Look for UL (Underwriters Laboratories) or ETL listings. These seals mean the product meets safety standards.

- Reusability: Some connectors, like lever nuts, allow you to easily open and reuse them. Twist-on connectors are usually single-use.

2. Important Materials

The materials used in wire connectors directly impact their durability and safety.

Housing Material

Most housings are made from durable, flame-retardant plastic. This plastic resists heat buildup. High-quality plastics will not easily crack or degrade over time.

Internal Conductors

The metal parts inside the connector grip the wires. These are usually made of high-conductivity metals like brass or copper. Good conductivity means less resistance, which keeps the connection cool. Cheaper connectors might use lower-grade alloys.

3. Factors That Improve or Reduce Quality

Good quality means better safety and longer-lasting connections. Poor quality can cause fires or frequent electrical failures.

What Makes a Quality Connector?

- Strong Grip: The connector must hold the wires tightly. If you pull on the wires after connecting, they should not slip out.

- Flame Resistance: High-quality plastic housing will self-extinguish if it gets too hot. This is a major safety feature.

- Corrosion Resistance: If the connector is used in damp areas, the metal components must resist rust or corrosion.

What Lowers the Quality?

Thin, brittle plastic housing is a red flag. Also, connectors that feel too light or loose often use poor internal springs or grips. Avoid connectors that lack clear safety markings.

4. User Experience and Use Cases

The best connector for you depends on where and how you use it.

Ease of Installation

For beginners, push-in or lever connectors often offer the best user experience. You simply strip the wire, push it in, or flip a lever. Twist-on connectors require more practice to ensure the wires are properly twisted together before capping.

Common Use Cases

- Lighting Fixtures: Often use small, twist-on or compact lever connectors for ceiling boxes.

- Outlet and Switch Wiring: Lever nuts are popular here because electricians often need to add or remove wires later when troubleshooting.

- Temporary or Testing Setups: Crimp connectors, which require a special tool, offer the most permanent and robust connection for fixed installations.

Always ensure the connector is rated for the environment. Dry indoor use allows for more material choices than damp outdoor or underground work.

Frequently Asked Questions (FAQ) about Wire Connectors

Q: What is the main difference between a wire nut and a lever connector?

A: A wire nut (twist-on) requires you to twist the wires together before screwing the cap on. A lever connector lets you open a small door, insert the wire, and close the lever for a quick lock.

Q: Do I need a special tool to use wire connectors?

A: For twist-on and lever connectors, you only need wire strippers. Crimp connectors, however, require a special crimping tool to secure the metal sleeve onto the wires.

Q: Can I reuse a standard twist-on wire nut?

A: It is generally not recommended. Once the plastic housing is stressed by twisting, its grip weakens. Reusing them lowers the safety margin of the connection.

Q: What does “UL Listed” mean on a connector?

A: “UL Listed” means an independent organization tested the connector and confirmed it meets established safety standards for electrical use.

Q: How do I know what wire gauge my wires are?

A: Wire gauge is printed along the insulation jacket of the wire itself. You look for the AWG number (e.g., 14 AWG or 12 AWG).

Q: Should I use connectors for outdoor wiring?

A: Yes, but only if the connector is specifically rated for outdoor or wet locations. Look for connectors that are sealed against moisture intrusion.

Q: What happens if I use a connector that is too small for my wires?

A: If the connector is too small, you cannot fit all the wires in properly. This creates poor contact, leading to resistance and dangerous heat buildup.

Q: What happens if I use a connector that is too large for my wires?

A: If the connector is too large, the internal gripping mechanism cannot hold the wires tightly. The connection will be loose, which can cause intermittent power loss or arcing.

Q: Is it okay to paint over wire connectors once installed?

A: No. Paint can sometimes compromise the insulation integrity or trap heat. Most electrical codes advise against covering connectors.

Q: How tightly must I strip the wire insulation?

A: You should strip just enough so that the bare copper wire extends slightly into the connector, but not so much that bare wire sticks out past the connector housing.

Hi, I’m Mallory Crusta, the heart and mind behind LovelyPetSpot.com.. As a passionate pet enthusiast, I created this space to share my experiences, expertise, and love for all things pets. Whether it’s helpful tips, heartfelt stories, or advice for pet parents, my mission is to make the journey of caring for your furry, feathery, or scaly friends as joyful and fulfilling as possible. Join me in celebrating the incredible bond we share with our animal companions!