Ever noticed that shiny, silvery coating on metal fences or roofing? That’s galvanization—a fantastic way to stop rust in its tracks! But here’s the tricky part: painting that smooth, slick surface can feel almost impossible. You might have tried painting it before, only to watch the paint bubble, peel, or flake off within months. It’s frustrating, right?

Choosing the correct paint for galvanized steel is more than just picking a color; it’s about chemistry. Standard paints just don’t stick well to the zinc layer. If you pick the wrong product, you waste time, money, and end up with a project that looks bad fast. This common headache stops many DIYers and contractors in their tracks.

This guide cuts through the confusion. We will clearly explain exactly what kind of paint bonds successfully to galvanized surfaces. You will learn the essential preparation steps and discover the top paint types that guarantee a long-lasting, beautiful finish. Get ready to learn the secrets to making your galvanized project look professional and stay protected for years to come!

Top Paint For Galvanized Steel Recommendations

- Ideal for use on wrought iron and spot-welded metal, gutters, chain-link fences and more to repair weathered galvanized finishes

- 93% pure zinc coating applies a galvanized film to renew weathered galvanized surfaces

- Dries to the touch in only 30 minutes and covers up to 12 sq. ft. per can

- Provides superior durability, resists corrosion, scratches and chips

- Weather and corrosion resistant primer bonds tightly to exterior/interior surfaces and specially formulated for aluminum galvanized metal

- Water-based acrylic formula provides a durable protective coating with excellent rust prevention

- Dries to touch in 1-2 hours and covers up to 55-90 sq. ft.

- Primer provides a base for excellent adhesion and withstands demanding, heavy-use environments

- Provides a smooth, zinc enhanced surface

- Forms a durable, crack resistant coating

- For best protection on bare steel

- VOC Compliant

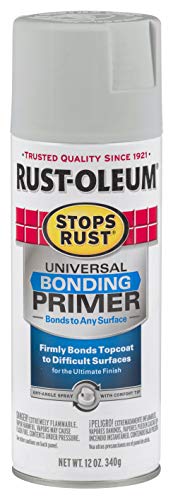

- Exterior/interior use, great for galvanized steel, wrought iron, railings, furniture, laminate, PVC, porcelain, masonry, glazed brick and more

- Low odor, low VOC water-based formula has excellent wet adhesion in moist or humid environments

- Dries to the touch in 30 minutes and covers up to 10-12 sq. ft.

- Prevents rust and corrosion for enhanced durability

- Exterior interior use, it firmly bonds topcoat to any surface like galvanized steel, wrought iron, railings, furniture, laminate, porcelain, masonry, glazed brick and more

- Durable, corrosion-resistant

- Covers up to 12 sq. ft.

- Maximum adhesion white primer

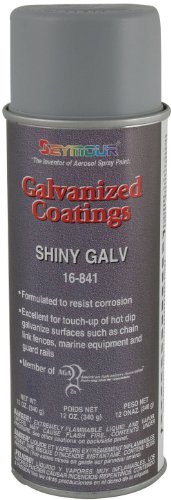

- A shiny zinc enhanced zinc coating that prevents rust and provides excellent outdoor protection

- This is the product of choice for the cosmetic restoration of galvanized metal, chain link fences, and guard rails

- Does not meet specifications calling for 65-Percent zinc in the can or greater than 90-Percent zinc in the dried paint film

- Fast dry, prevents rust, and has excellent outdoor durability

- RustSeal is an incredible, single-component, ready-to-use, high solids content, rust preventive coating and stop rust paint with insane sealing properties.

- No other brand is tougher on rust! Using premium quality materials and advanced color formulations, this high tech performance coating is the present-day answer for 21st century rust protection.

- RustSeal is the most permanent cost-effective solution for stopping rust and corrosion anyplace where it is a problem: home, automotive, industry, fleet, farm & more!

- Unlike other corrosion treatments, RustSeal is an enhancement that lasts. Water and air are locked out, therefore oxidation, the precursor to rust, cannot take hold.

- Ideal for refinishing exterior metal surfaces including refrigerators, dishwashers, laundry machines and more

- Epoxy formula creates an ultra hard, washable surface that withstands everyday wear

- Dries to the touch in 2-4 hours and covers approximately 7 sq. ft. per can

- Provides a durable surface with an exceptional glossy shine

The Ultimate Buying Guide: Painting Galvanized Steel Like a Pro

Galvanized steel is strong. It resists rust because of a protective zinc coating. But that zinc layer makes painting tricky. If you use the wrong paint, it will peel right off! This guide helps you pick the perfect paint so your project lasts for years.

Key Features to Look For

When buying paint for galvanized steel, you must look for specific features. These features help the paint stick well to the slick zinc surface.

- **Adhesion Promoter:** This is the most important feature. Good paints contain chemicals that help the paint grab onto the zinc.

- **Flexibility:** Steel moves a little when it gets hot or cold. Your paint must stretch and shrink with the steel. Brittle paints crack easily.

- **Rust Inhibitors (Even though it’s galvanized):** While the zinc protects the steel, good paint adds an extra layer of defense against moisture.

- **UV Resistance:** If the steel is outside, the paint needs to resist fading and breaking down from sunlight.

Important Materials: What’s Inside the Can?

The type of paint matters a lot more than the color. You need the right chemical base to bond with the galvanized surface.

1. Water-Based Acrylics (Latex): These are often the best choice for DIYers. Modern, high-quality acrylics are formulated to stick directly to new or aged galvanized metal. They clean up easily with water and dry fast.

2. Epoxy Primers: Epoxies create an extremely tough, chemical-resistant bond. They are often used as a primer coat before applying a topcoat. They provide superior adhesion.

3. Oil-Based Paints (Use with Caution): Traditional oil-based paints often struggle to stick to galvanized metal unless you use a very specific bonding primer first. They can sometimes react poorly with the zinc coating over time.

Factors That Improve or Reduce Quality

The paint quality depends on two main things: the paint itself and how you prepare the surface.

Factors that Improve Quality:

Proper Surface Preparation: This is non-negotiable. You must clean the surface thoroughly. New galvanized steel releases zinc byproducts (called “mill scale”) that repel paint. You must wash this off using a degreaser or a mild etching solution (like vinegar or a specialized cleaner). This process creates a slightly rough surface for the paint to grip.

Using the Right Primer: Always use a primer specifically labeled for galvanized metal, even if the topcoat claims to be “one-coat.” The primer acts as the glue between the slick zinc and the colored topcoat.

Factors that Reduce Quality:

Painting Too Soon: If the galvanized steel is brand new (less than six months old), it is often too slick. Wait a few months for it to weather naturally, or use a chemical etching solution to prepare it.

Ignoring Temperature Rules: Painting when it is too cold or too humid stops the paint from curing (drying and hardening) correctly. This leads to soft, sticky paint that peels easily.

User Experience and Use Cases

People paint galvanized steel for two main reasons: looks and extra protection.

Outdoor Projects (Fences, Gutters, Sheds): For these uses, users prefer durable acrylic or epoxy systems. They need paints that handle rain, snow, and intense sun without chalking (turning powdery).

Indoor Projects (Ductwork, Storage Bins): Indoor items need less UV protection but still require good adhesion. Water-based acrylics usually work great here because they have low odor.

User Tip: Experienced painters always test a small, hidden area first. They apply the paint and let it dry fully, then try to scratch it with a fingernail. If it scratches off easily, the preparation wasn’t good enough, or the paint is wrong.

10 Frequently Asked Questions (FAQ) About Painting Galvanized Steel

Q: Can I paint brand new galvanized steel right away?

A: No. New galvanized steel has a slick coating. You must clean it, let it weather for a few months, or chemically etch the surface before painting.

Q: What is the absolute best type of paint for galvanized steel?

A: High-quality, 100% acrylic latex paints formulated with special adhesion promoters are usually the best and easiest choice for most people.

Q: Do I really need a primer on galvanized metal?

A: Yes. A primer specifically designed for galvanized metal ensures the paint sticks securely to the slick zinc coating.

Q: What should I use to clean the surface before I start painting?

A: Use a strong degreaser or a specialized metal cleaner. For old steel, a stiff brush and soapy water might be enough after washing off loose dirt.

Q: Can I use regular exterior house paint on galvanized steel?

A: Generally, no. Regular exterior paint lacks the special bonding agents needed to stick to the non-porous zinc surface.

Q: How long does the paint need to cure before it is safe to touch?

A: Most acrylic paints are dry to the touch in a few hours. However, they need 3 to 7 days to fully cure (harden) before they can handle heavy use or moisture exposure.

Q: Will oil-based paint work on galvanized steel?

A: It can, but only if you use a specialized bonding primer first. Oil paint alone often fails to bond correctly with the zinc.

Q: What happens if I don’t prep the surface correctly?

A: The paint will look fine at first, but over time, moisture and temperature changes will cause the paint to bubble, flake, and peel off in sheets.

Q: Should I sand the galvanized surface?

A: Light scuffing with fine sandpaper (like 220 grit) helps, especially on very smooth surfaces. This slightly roughs up the zinc, helping the primer grip better.

Q: Does the color of the paint affect how long it lasts?

A: Yes. Darker colors absorb more heat from the sun, which causes the metal underneath to expand and contract more. This extra movement can stress the paint bond over time.

Hi, I’m Mallory Crusta, the heart and mind behind LovelyPetSpot.com.. As a passionate pet enthusiast, I created this space to share my experiences, expertise, and love for all things pets. Whether it’s helpful tips, heartfelt stories, or advice for pet parents, my mission is to make the journey of caring for your furry, feathery, or scaly friends as joyful and fulfilling as possible. Join me in celebrating the incredible bond we share with our animal companions!