Ever held a knife that felt just right in your hand? That perfect balance and edge that stays sharp? The secret to that amazing knife often lies in the steel it’s made from. Choosing the right steel for your knife-making project can feel like navigating a maze. You hear terms like “high carbon” and “stainless,” and it’s easy to feel lost. What steel will hold a great edge? Which one resists rust the best? These choices directly impact how well your knife performs and how long it lasts.

Don’t let confusing metal names slow down your craft. This post cuts through the confusion. We will explore the most popular and reliable steels knife makers use today. You will learn what makes each type unique, from its toughness to how easy it is to sharpen. By the end, you will confidently pick the perfect steel for your next blade, avoiding costly mistakes.

Top Steel For Knife Making Recommendations

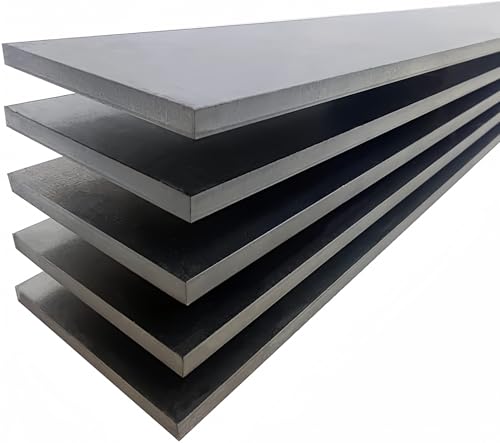

- BEST CHOICE FOR YOUR KNIFE:We provide you 1095 steel flat stock, the most perfect knife making steel, selected by lots of famous knife manufacturers. The super toughness and grinding degree make it very suitable for your handmade DIY knives.

- COLD ROLLED & ANNEALED:We have annealed the high carbon steel to improve its machinability. You can easily process your knife steel that has good machinability, saving your time and abrasive belts.

- SPECIFICATIONS:Each package contains four 1095 Steel Bar Stock, all of which has a size of 12" x 1.5" x 0.12". There are enough knife making steel for you. Create your own custom knife that will last a lifetime.

- PERFECT PACKAGING:We use three layers of rust-proof packaging for 1095 steel flat stock: rust-proof oil, rust-proof paper, and bubble bags to prevent your knife making steel from rusting or being damaged.

- BEST CHOICE FOR YOUR KNIFE:We provide you 1095 steel flat stock, the most perfect knife making steel, selected by lots of famous knife manufacturers. The super toughness and grinding degree make it very suitable for your handmade DIY knives.

- COLD ROLLED & ANNEALED:We have annealed the high carbon steel to improve its machinability. You can easily process your knife steel that has good machinability, saving your time and abrasive belts.

- SPECIFICATIONS:Each package contains four 1095 Steel Bar Stock, all of which has a size of 12" x 1.5" x 0.12". There are enough knife making steel for you. Create your own custom knife that will last a lifetime.

- PERFECT PACKAGING:We use three layers of rust-proof packaging for 1095 steel flat stock: rust-proof oil, rust-proof paper, and bubble bags to prevent your knife making steel from rusting or being damaged.

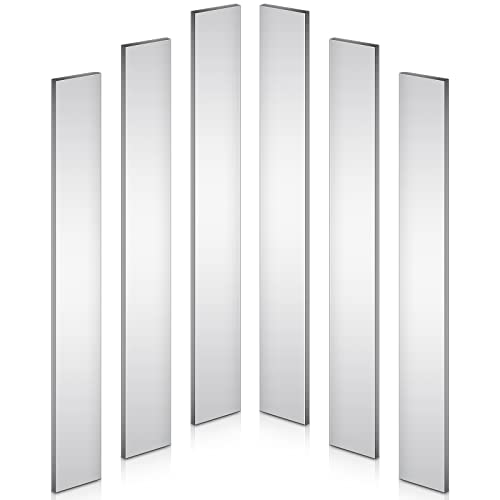

- Package Including: you will get 6 pieces of silver flat steel bars coated with slushing oil in a package, sufficient quantity can easily meet your need for knife making or DIY, you can use these billets to forge any shape of knife as you want

- Quality Material: 1084 steel bar is a kind of high carbon steel, suitable for cutting tools, and the product adopts cold rolling process, its surface is very smooth, precision of incision, not easy to rust

- Detailed Size Information: the size of the 1084 steel flat stock is about 12" x 1.5" x 0.12"/ 30.48 x 3.81 x 0.3 cm, you can make knife according to your needs, please note: manual measurement, please allow a little error

- Easy to Operate: this 1084 steel for knife making is easy to process, easy to heat treatment, easy to cut after annealing, you can forge steel according to different needs into your satisfactory products

- Specifications - Dimensions are 1.5" x 12" x 1/8",4 Pcs of 1084 Steel Flat Stock.

- Cold Rolled and Annealed-Improve the machinability and performance of 1084 flat steel, save time and abrasive belts.

- Moderate carbon content, the steel balances strength and toughness well for general fabrication and manufacturing use. It is not too brittle while providing solid performance.

- Versatile Shaping-The flat steel can be cut, bent, machined or otherwise formed into various components and parts. Its square edges are easy to grip during manual operations.

- Quality Material: Made of premium 1095 steel, known for its high hardness and wear resistance, featuring good elasticity and toughness, won't break or deform easily, ideal for various applications and relied upon for long term use.

- Cold Rolled: Annealed the high carbon steel to improve its machinability. You can easily process your knife steel, saving your time and abrasive belts.

- Versatile Usage: Super toughness and grindability, perfect for hand DIY making blades, knives, hand tools, spacers, etc. Plus, it's suitable for residential structural use, whether indoors or outdoors.

- Smoothly Surface: Each steel sheet is pre-oiled, provides grip and anti slip characteristics as an added benefit.

- EXCEPTIONAL QUALITY - Crafted in the USA using 5160 steel, our products meet exacting quality standards, assuring exceptional performance in your knife-making projects.

- RELIABLE CONSISTENCY - Our small batch production and rigorous inspections maintain a consistent product every time you order, whether you're working with 5160 steel for knife making, 5160 steel flat stock, or any other knife steel.

- VERSATILE FOR PROFESSIONALS & HOBBYISTS - Ideal for both professional knife makers and hobbyists, our high carbon steel excels in any project, making it a reliable choice for all your knife making endeavors.

- TRUST IN AMERICAN CRAFTSMANSHIP - While many competitors source from China, we proudly manufacture all our products in the USA, including our knife blanks, forging tools and equipment, and other knife making supplies. Trust in the quality and authenticity of Patriot Steel for your knife-making needs.

- USA-MILLED 1095 HIGH CARBON MATERIAL – Patriot Steel knife making steel bars are made from 1095 high carbon flat blanks and milled in the USA for consistency and performance across forging, heat treating, and bladesmithing applications.

- READY-TO-FORGE ANNEALED BLANKS – Cold Rolled Annealed (CRA) 1095 high carbon steel reduces prep time and effort, helping knifemakers work more efficiently with fewer tools while preserving sanding belts during the blade shaping process.

- BUILT FOR BLADESMITHING & FORGING – Ideal for crafting custom blades, power knives, or starter blades, this forging steel reinforces a variety of forges and heat treating methods for home workshops, beginners, or experienced professionals.

- CONSISTENT TOOL STOCK EVERY TIME – Each order delivers knife making steel bars and flat blanks with uniform dimensions and reliable hardness, making it a dependable material for your forging kit or tool equipment.

- Specifications - Dimensions are 1.5" x 12" x 0.12", package contains 4 pieces of 1095 steel flat stock.

- Cold Rolled and Annealed - enhances the mechanical and processing properties of flat steel bars, saving time and sanding belts.

- High Quality Material - 1095 is the highest carbon grade, and billets made from high carbon steel provide excellent heat treatment results.

- Packaging-Hand packed in three layers of rust-proof packaging: rust-proof oil, rust-proof paper and bubble wrap to prevent rusting or damage.

The Ultimate Buying Guide for Steel For Knife Making

Choosing the right steel makes a huge difference in your knife. Good steel means a sharp, long-lasting blade. This guide helps you pick the best metal for your needs.

1. Key Features to Look For

When you look at knife steel, three main things matter most. These features decide how well your knife will work.

- Edge Retention: This means how long the knife stays sharp. Steel with high wear resistance holds an edge longer.

- Toughness: This is the steel’s ability to resist chipping or breaking when dropped or used hard. A tough blade bends a little before it snaps.

- Corrosion Resistance: This is how well the steel fights rust. If you work near water or use your knife in the kitchen, you need good rust resistance.

2. Important Materials in Knife Steel

Knife steel is an alloy—a mix of iron and other metals. These added elements change the steel’s properties.

Carbon Content (The Foundation)

Carbon is the most crucial element. More carbon usually means harder steel and better edge retention. However, too much carbon can make the steel brittle.

Alloying Elements

- Chromium (Cr): Added in large amounts (over 12%), chromium makes steel “stainless.” It greatly improves rust resistance.

- Vanadium (V): This element creates very hard carbides (tiny hard spots) in the steel. This boosts wear resistance and edge holding.

- Molybdenum (Mo): Molybdenum increases toughness and helps the steel hold its strength at high temperatures.

3. Factors That Improve or Reduce Quality

The type of steel is only half the story. How the steel is treated affects its final quality.

Heat Treatment: The Magic Step

Proper heat treatment unlocks the steel’s potential. The steel must be heated to a specific temperature and then cooled quickly (quenched). This hardens the metal.

Tempering: Balancing Hardness

After quenching, the steel is often too brittle. Tempering involves reheating the steel gently. This reduces brittleness while keeping most of the hardness. Poor tempering leads to soft or easily chipped blades.

Contaminants (Quality Reduction)

Low-quality steel often contains too many impurities, like sulfur or phosphorus. These unwanted materials weaken the steel structure, making it prone to cracking during forging or use.

4. User Experience and Use Cases

Your intended use dictates the best steel choice. One steel is rarely perfect for every job.

High-Performance Blades (Maximum Edge Retention)

If you want a knife that stays sharp for a very long time (like for detailed cutting or heavy wood carving), look for high-alloy steels (e.g., CPM S30V or M390). These steels often sacrifice some toughness for superior edge holding.

Everyday Carry (EDC) and Kitchen Knives (Balance)

For general use, you need a good balance. Steels like 154CM or standard D2 offer excellent edge retention while remaining tough enough for daily tasks. Stainless steels (like AEB-L) are great for kitchen use because they clean easily and resist stains.

Tough Field Knives (Maximum Toughness)

If you need a knife that can handle hard abuse, like chopping or prying (though prying is discouraged!), choose very tough, high-carbon steels (like 1095 or O1). These are easier to sharpen but will need more frequent touch-ups and require oiling to prevent rust.

10 Frequently Asked Questions (FAQ) About Knife Steel

Q: What is the difference between Carbon Steel and Stainless Steel?

A: Carbon steel has less chromium, making it very tough and easy to sharpen. However, it rusts easily. Stainless steel has more chromium, which stops rust but sometimes makes the steel slightly harder to sharpen.

Q: Is harder steel always better steel?

A: No. Very hard steel holds an edge longer, but it becomes brittle. If it is too hard, the blade might chip when you hit something hard.

Q: What does “HRC” mean?

A: HRC stands for Rockwell Hardness C scale. It is the standard way scientists measure how hard the steel is. Most good knives fall between 58 and 63 HRC.

Q: Should I worry about the steel’s grain structure?

A: Yes. The grain is how the metal crystals line up. Good makers ensure the grain is fine and aligned correctly, which makes the blade stronger and less likely to break.

Q: Is it hard to sharpen high-wear steels?

A: Yes, generally. Steels designed to hold an edge for a long time (like those with lots of Vanadium) are very hard. You need high-quality sharpening stones to bring them back to a fine edge.

Q: What is tool steel used for in knives?

A: Tool steels, like D2, were first made for industrial cutting tools. They offer a great mix of wear resistance and toughness, making them popular for mid-to-high-end fixed blades.

Q: What is the best beginner steel to practice sharpening on?

A: Simple carbon steels like 1080 or 1095 are excellent. They are softer and respond quickly to sharpening stones, letting you feel the edge develop.

Q: How does powdered metallurgy affect knife steel?

A: Powdered metallurgy (like CPM steels) mixes the metal as a fine powder before pressing it. This creates a very uniform, fine grain structure, which usually results in better overall performance.

Q: Does the finish (like satin or mirror) affect performance?

A: No. The finish is purely cosmetic. It does not change how sharp the edge gets or how long it stays sharp.

Q: Can I use mild steel for a knife?

A: Mild steel (like plain low-carbon steel) is too soft. It will dull instantly and will not hold a usable edge because it cannot be hardened properly.

Hi, I’m Mallory Crusta, the heart and mind behind LovelyPetSpot.com.. As a passionate pet enthusiast, I created this space to share my experiences, expertise, and love for all things pets. Whether it’s helpful tips, heartfelt stories, or advice for pet parents, my mission is to make the journey of caring for your furry, feathery, or scaly friends as joyful and fulfilling as possible. Join me in celebrating the incredible bond we share with our animal companions!